Tundish Nozzle Refractories in Pakistan

Tundish Nozzle Refractories in Pakistan

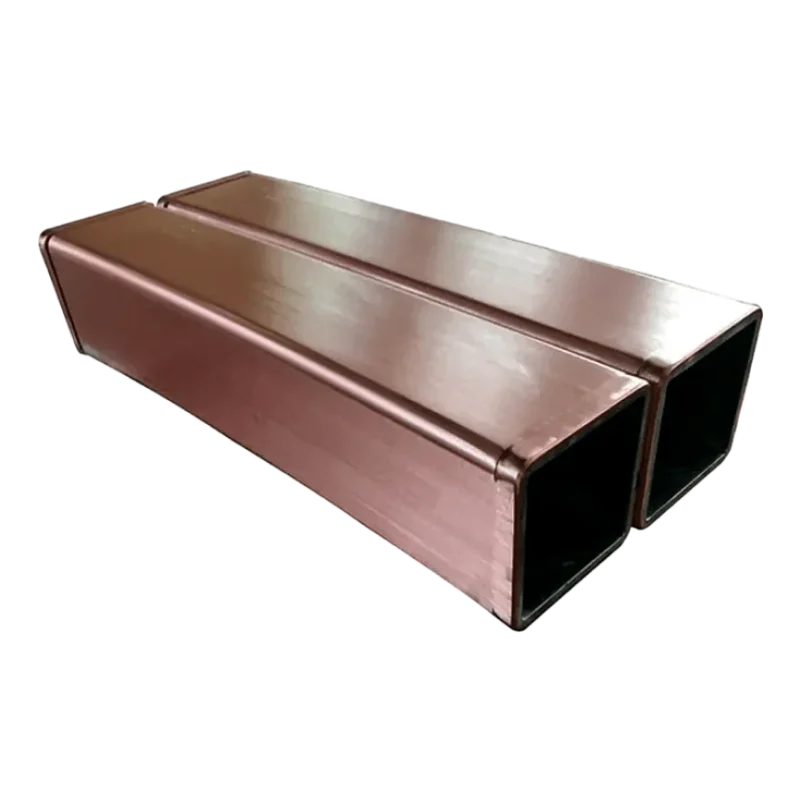

Looking for durable Tundish Nozzle Refractories in Pakistan? Our nozzles are engineered to meet the demanding needs of the steel industry. Made from high-grade refractory materials, these nozzles ensure consistent molten steel flow, reduced clogging, and optimal performance during continuous casting operations.

Tundish Nozzle Refractories in Pakistan – Reliable Flow Control for Steel Casting

Tundish nozzle refractories are specialized components made from heat-resistant materials used to control the flow of molten steel from the tundish to the mold in continuous casting machines. These nozzles are crucial for minimizing inclusions, regulating casting speed, and enhancing the overall quality of steel billets, blooms, or slabs.

Features of Our Tundish Nozzles

-

High Thermal Stability (up to 1600°C)

-

Precision-Bored for Accurate Flow Control

-

Clog-Resistant Designs

-

Available in Various Sizes & Shapes

Technical Specifications

| Property | Details |

| Material | High Alumina, Magnesia, Zirconia |

| Temperature Range | Up to 1600°C |

| Bore Sizes | 10mm – 30mm |

| Shape Options | Straight, Conical, Stepped |

| Compatibility | Slide Gate & Stopper Rod Systems |

- Material Composition: Made from advanced refractory materials with high thermal resistance and excellent wear properties.

- Precision Engineering: Designed for optimal flow control, enabling a stable and consistent stream of molten metal into the mold.

- High-Temperature Tolerance: Able to withstand the intense heat of molten steel, ensuring structural integrity and reliable performance over extended casting cycles.

Applications in the Steel Industry

-

Billet and Bloom Casting

-

Continuous Casting Machines (CCM)

-

Steel Melting Shops (SMS)

-

Mini and Integrated Steel Plants

Why Choose Us for Tundish Nozzle Refractories in Pakistan?

-

Tailored to meet the needs of local steel producers

-

Cost-effective and readily available with minimal lead time

-

Backed by technical support and custom engineering services

Available Variants

-

Zirconia Core Nozzles

-

Monoblock Nozzles

-

Custom Stepped-Bore Nozzles

Enhance Your Casting Efficiency

Whether you’re operating a high-speed billet caster or a compact mini mill, our Tundish Nozzle Refractories in Pakistan offer the flow reliability and thermal resistance needed to keep your process running smoothly. Improve your productivity and casting quality with precision-engineered solutions.

| Enhanced Casting Quality | Provides smooth, controlled flow, reducing turbulence and preventing inclusions or impurities, resulting in higher-quality cast products. |

|---|---|

| Durable and Long-Lasting | Manufactured from wear-resistant refractory materials, reducing nozzle erosion and ensuring longer service life. |

| Consistent Performance | Designed to deliver stable and predictable flow, maintaining consistent steel quality and reducing the risk of casting defects. |

| Easy Replacement | Available in multiple sizes and shapes to fit different tundish configurations, making replacement and maintenance straightforward. |

Reviews

There are no reviews yet.