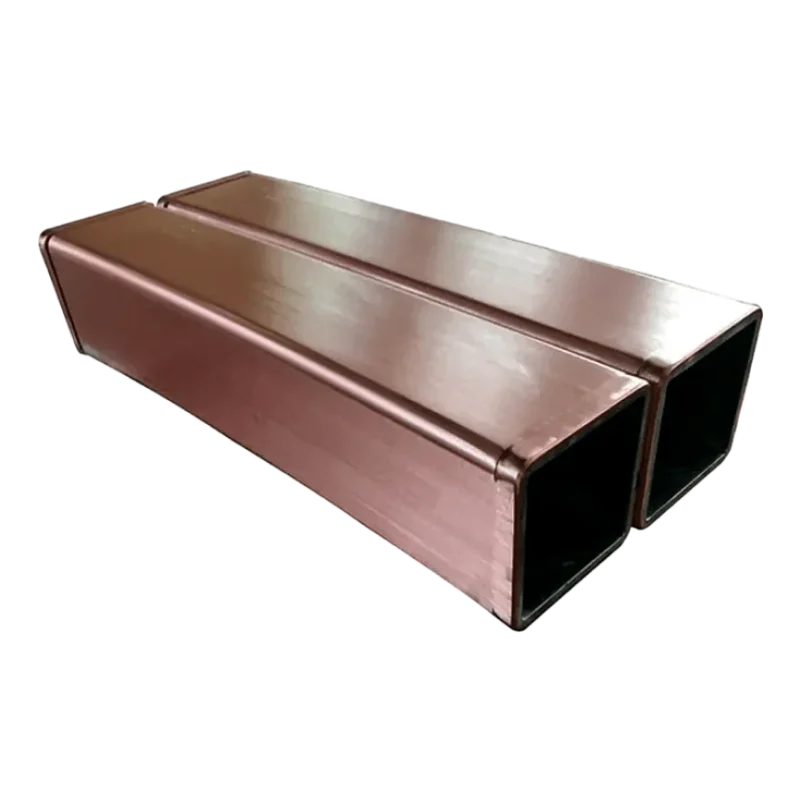

Round Copper Mould Tube for Continuous Casting in Steel Mills

Round Copper Mould Tube for Continuous Casting in Steel Mills

Optimize your continuous casting with our Round Copper Mold Tubes—designed for rapid heat transfer, uniform cooling, and durability. Perfect for casting steel billets, these tubes ensure high-quality production and extended service life in demanding steel manufacturing environments.

Round Copper Mould Tubes – High-Performance Cooling for Superior Casting

Our Round Copper Mould Tubes are engineered for precision and longevity, playing a critical role in the continuous casting process in steel mills. Manufactured from high-conductivity copper and customized to match your machine specifications, our mould tubes ensure optimal heat transfer and consistent casting performance.

Whether you’re producing billets, blooms, or rounds, our Copper Mould Tubes are trusted by leading steelmakers for their dimensional accuracy, anti-wear coatings, and reliable thermal performance.

Technical Specifications

- Material Composition: Constructed from high-quality copper for superior thermal conductivity, enabling fast and even heat dissipation.

- Coating Options: Available with chrome or nickel plating, enhancing surface hardness, corrosion resistance, and mold tube longevity.

- Design Precision: Engineered for optimized cooling dynamics across the entire tube, preventing hot spots and reducing casting defects.

Product Specifications

| Product Name | Size (Inner Diameter) | Thickness (mm) | Length (mm) | Casting Radius (mm) |

| Round Copper Mould Tube | Ø150 mm | 8 mm | 900 mm | 6000 mm |

| Round Copper Mould Tube | Ø160 mm | 10 mm | 800 mm | 5000 mm |

| Round Copper Mould Tube | Ø180 mm | 12 mm | 1000 mm | 9000 mm |

| Round Copper Mould Tube | Ø200 mm | 12 mm | 1200 mm | 10000 mm |

Key Features

-

Material: High-purity copper (99.99%)

-

Coating Options: Hard chrome, nickel plating, or Cr-Zr alloy coating

-

Shape: Round

-

Applications: Continuous casting of steel billets and rounds

-

Customization: Available in various sizes and radii

-

Cooling Efficiency: Superior thermal conductivity for faster solidification

-

Service Life: Long-lasting with reduced downtime

Applications

Our Round Copper Mould Tubes are widely used in:

-

Steel billet casting

-

Continuous casting machines (CCM)

-

Steel mills and foundries

Why Choose Us?

-

Strict quality control

-

Fast delivery and global shipping

-

Experienced technical support team

Get a Quote Today

Improve your steel mill’s performance with our premium round copper mould tubes. Contact us today to get a custom quote or request more information.

| Exceptional Heat Transfer | High-purity copper ensures quick and uniform heat extraction, minimizing surface defects like cracks and improving billet quality. |

|---|---|

| Long Service Life | Chrome or nickel coatings increase resistance to wear, scaling, and corrosion, extending the mold tube’s operational lifespan. |

| Improved Product Quality | Uniform cooling prevents internal stresses and surface inconsistencies, resulting in smooth, high-quality billets with fewer defects. |

Reviews

There are no reviews yet.