High Speed Steel Roll (HSS) in Pakistan

High Speed Steel Roll (HSS) in Pakistan

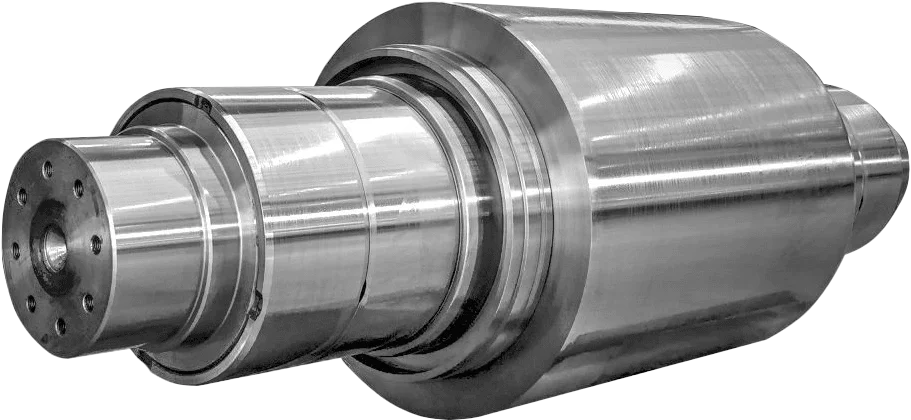

Boost your mill’s productivity with our High Speed Steel Rolls (HSS) — engineered for extreme durability, unmatched wear resistance, and high thermal stability. Perfect for hot strip finishing stands, our HSS rolls deliver longer life and fewer roll changes, saving you time and cost.

Request a Quote / Inquiry

Enhancing Rolling Mill Performance with Premium High Speed Steel (HSS) Rolls

High Speed Steel Rolls (HSS Rolls) are advanced-grade work rolls designed to withstand extreme heat, pressure, and wear in hot rolling applications. At UNISONS, we offer top-quality High Speed Steel Roll (HSS) in Pakistan specifically engineered for long-lasting performance in steel rolling mills.

These rolls provide an excellent balance of hardness, toughness, and thermal resistance, making them ideal for use in finishing stands of hot strip mills. Their superior wear resistance reduces roll changes and improves productivity—making them a cost-effective choice for high-speed, high-load rolling operations.

Technical Data Table for High Speed Steel Rolls (HSS)

| Property | Specification |

| Product Name | High Speed Steel Roll (HSS) |

| Application | Finishing stands in hot strip mills |

| Hardness (HSD) | 80–90 HSD |

| Material Composition | High-carbon steel + Cr, Mo, V, Ni |

| Working Temperature | Up to 700°C |

| Surface Hardness Depth | 15–25 mm |

| Core Toughness | High core strength to prevent spalling |

| Manufacturing Method | Static or centrifugal casting |

| Finish | Machined or Ground |

| Standard Sizes | Customizable as per client request |

- Material Composition: High-Speed Steel alloyed with chromium, vanadium, and molybdenum for enhanced hardness, thermal resistance, and wear properties.

- Hardness Levels: Typically reaches 80 HSC (Rockwell C Scale) or higher, maintaining hardness even at elevated temperatures.

- Thermal Stability: Designed to perform under high thermal and mechanical stresses, minimizing distortion and ensuring prolonged life.

Key Features of Our HSS Rolls:

-

Excellent Wear Resistance: Superior alloying elements resist abrasive wear at high temperatures.

-

High Thermal Fatigue Strength: Withstands intense heat cycling during rolling operations.

-

Dimensional Stability: Maintains shape under high loads, ensuring consistent roll performance.

-

Longer Service Life: Reduces roll replacement frequency and downtime.

Applications of HSS Rolls in Steel Rolling Mills

High Speed Steel Rolls are widely used in:

-

Hot strip mills

-

Bar and wire rod mills

-

Section mills

-

High-speed finishing stands

They are particularly effective where high rolling speeds and tight tolerance requirements exist.

Why Choose Us for HSS Rolls in Pakistan?

-

In-house inspection and quality control

-

Custom roll design and dimensions

-

Fast delivery to any region in Pakistan

-

Technical support and performance evaluation

Request a Quote

Looking for High Speed Steel Roll (HSS) in Pakistan? Get in touch with our team today for expert advice and competitive pricing tailored to your production needs.

| Superior Wear Resistance | High-speed steel composition enhances resistance to wear and abrasion, reducing roll replacement frequency and maintenance costs. |

|---|---|

| Consistent Surface Quality | Ensures a uniform, high-quality finish on steel products, minimizing surface defects and maintaining product integrity. |

| Extended Service Life | Durable in extreme rolling conditions, these rolls offer a longer operational lifespan than conventional rolls, enhancing productivity. |

| High-Temperature Stability | Retains hardness and resistance under high temperatures, preventing distortion and maintaining roll geometry. |

Reviews

There are no reviews yet.