How Industrial Automation Enhances Efficiency and Reduces Costs

Tuesday, March 25, 2025

Industrial automation is a game-changer for sectors like steel, cement, and fertilizer manufacturing, helping companies improve efficiency, safety, and operational consistency. However, implementing automation systems also comes with its share of challenges. In this blog, we explore five of the most common hurdles industries face during automation—and practical ways to overcome them.

One of the first barriers industries encounter is the upfront cost of automation systems—equipment, sensors, SCADA software, and integration. For many organizations, this initial price tag can seem daunting.

View automation as a long-term investment. Cost savings from increased efficiency, reduced labor, and minimized downtime quickly justify the initial spend. Look for modular solutions to spread costs over time. Partnering with experienced automation providers like Unisons ensures strategic planning to maximize ROI from day one.

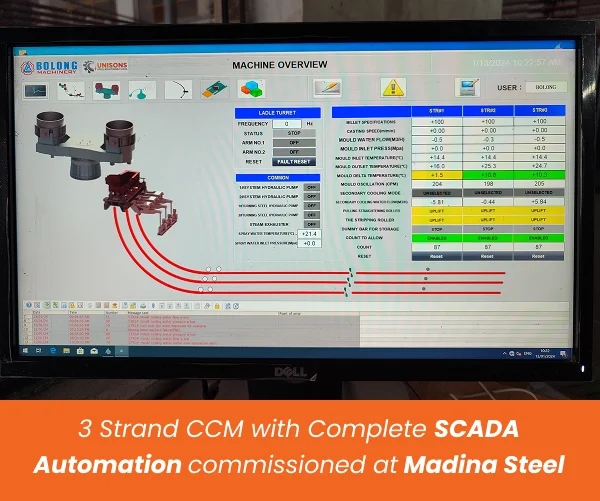

Many factories still operate older machines that aren’t designed for digital integration. Replacing all existing hardware may be infeasible due to budget or time constraints.

Use retrofit automation solutions that allow sensors and SCADA modules to communicate with older equipment. Unisons has experience in integrating modern control systems with existing plant setups, minimizing disruptions and ensuring compatibility with both old and new systems.

Transitioning to automated systems can create a skills gap, as traditional operators may lack experience with digital tools and interfaces.

Offer comprehensive training programs and user-friendly interfaces. At Unisons, we provide hands-on training to ensure your team understands how to operate and maintain new systems with confidence. We are able to design user-friendly HMI/SCADA dashboards that simplify complex operations for operators.

Automation systems generate vast amounts of data—but without the right tools and strategies, this data can overwhelm rather than inform.

Implement smart data filtering, visualization dashboards, and performance tracking tools. Focus on actionable insights rather than raw numbers. Unisons helps clients develop intuitive dashboards and KPIs that turn complex data into useful decision-making tools.

Connecting equipment to networks introduces new cybersecurity vulnerabilities that must be proactively managed.

Use encrypted communication protocols, role-based access controls, regular software updates, and real-time monitoring. Unisons incorporates robust cybersecurity measures into every automation system we deliver, including industrial firewalls and secure data transmission protocols.

As operations grow, automation systems must scale without costly redesigns.

Choose modular platforms that can expand with your needs. Unisons designs scalable automation architectures that support future upgrades and integrations, ensuring long-term performance.

While industrial automation offers transformative benefits, it’s important to approach it with a clear understanding of the challenges. From cost concerns to legacy integration and data management, each obstacle can be overcome with the right strategy and partner.

Unisons has successfully commissioned automation systems—including SCADA integration—across numerous industrial facilities. Our team is equipped to deliver custom solutions tailored to your operations, helping you modernize with confidence and efficiency.

Contact us today to learn how we can support your automation journey.