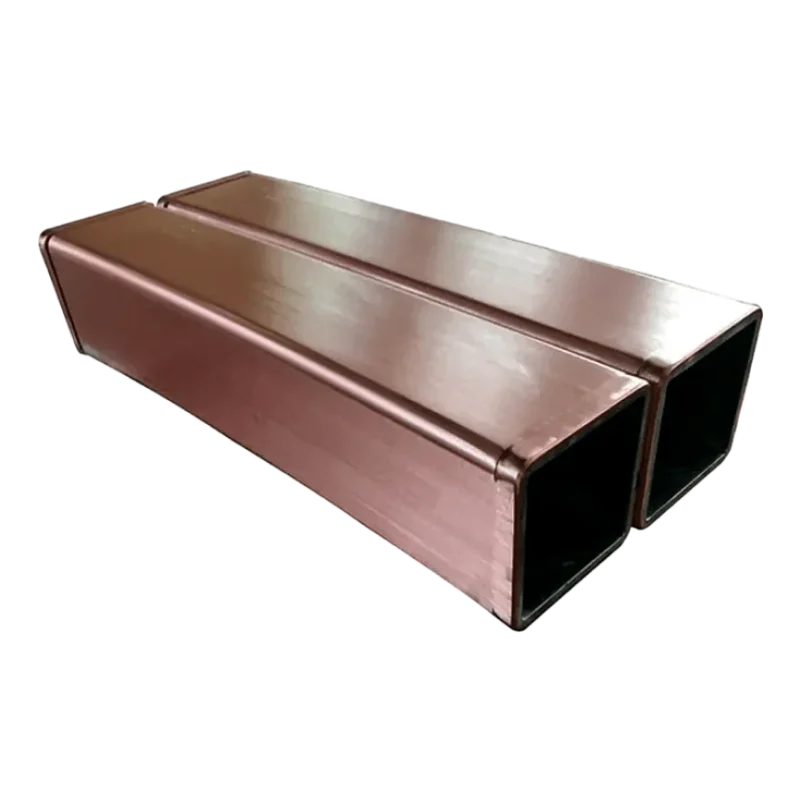

Rectangle Copper Mould Tube for Continuous Casting in Steel Mills

Rectangle Copper Mould Tube for Continuous Casting in Steel Mills

Ensure optimal steel quality with our Rectangular Copper Mold Tubes—designed for high thermal conductivity, precision cooling, and durability. Perfect for continuous casting, these tubes deliver reliable performance and extended service life in demanding steel manufacturing processes.

Rectangle Copper Mould Tube – Precision Cooling for Superior Casting

Unisons Steel Solutions offers Rectangle Copper Mould Tubes specially designed for continuous casting in steel manufacturing. Built for durability, thermal efficiency, and casting precision, our mould tubes are widely used across Pakistan’s leading steel mills and continuous casting machine installations.

Product Overview

Rectangle copper mould tubes are engineered to shape molten steel into rectangular billets during the casting process. They provide excellent heat transfer, high wear resistance, and long service life, making them a critical component in improving casting quality and reducing downtime.

Rectangle Copper Mould Tube- Technical Specifications

| Product Name | Size (mm) | Thickness (mm) | Length (mm) | Radius (mm) |

| Rectangle Copper Mould Tube | 150 × 200 | 12 | 800 – 1000 | 6000 – 9000 |

| Rectangle Copper Mould Tube | 160 × 240 | 13 | 800 – 1000 | 6000 – 9000 |

| Rectangle Copper Mould Tube | 180 × 300 | 14 | 900 – 1200 | 8000 – 10000 |

| Rectangle Copper Mould Tube | Custom sizes available | As per request | As per design | As per machine |

- Material Composition: Manufactured from high-purity copper for excellent thermal conductivity, ensuring rapid and even heat extraction.

- Coating Options: Available with chrome or nickel plating, providing enhanced surface hardness, corrosion resistance, and extended lifespan.

- Precision Design: Precisely engineered for uniform cooling across the mold surface, reducing defects and improving product consistency.

Key Features

-

High thermal conductivity for efficient cooling

-

Customizable sizes to fit your CCM design

-

Premium copper alloy (TP2/Cu-DHP) for high strength and long life

-

Internal coatings such as Cr, Ni, or Ni-Co for enhanced wear resistance

-

Consistent internal taper for optimal billet extraction

Applications

-

Billet casting in continuous casting machines (CCMs)

-

Used in steel plants producing rectangular billets

-

Ideal for high-speed casting operations

Why Choose Unisons in Pakistan?

-

Locally available stock with fast delivery

-

Backed by technical support and consultancy

-

Designed to match international quality standards at competitive prices

-

Proven performance in major steel mills across Pakistan

Get in Touch

Looking to source Rectangle Copper Mould Tubes in Pakistan?

Contact us today to request a quote or speak with our engineering team.

| Enhanced Thermal Conductivity | High-purity copper provides quick and uniform heat extraction, minimizing surface cracking and structural defects in the cast. |

|---|---|

| Extended Service Life | Chrome or nickel coatings increase resistance to wear and corrosion, reducing maintenance frequency and cost. |

| Improved Steel Quality | Uniform cooling reduces the likelihood of internal stress and cracks, resulting in higher-quality steel products. |

Reviews

There are no reviews yet.