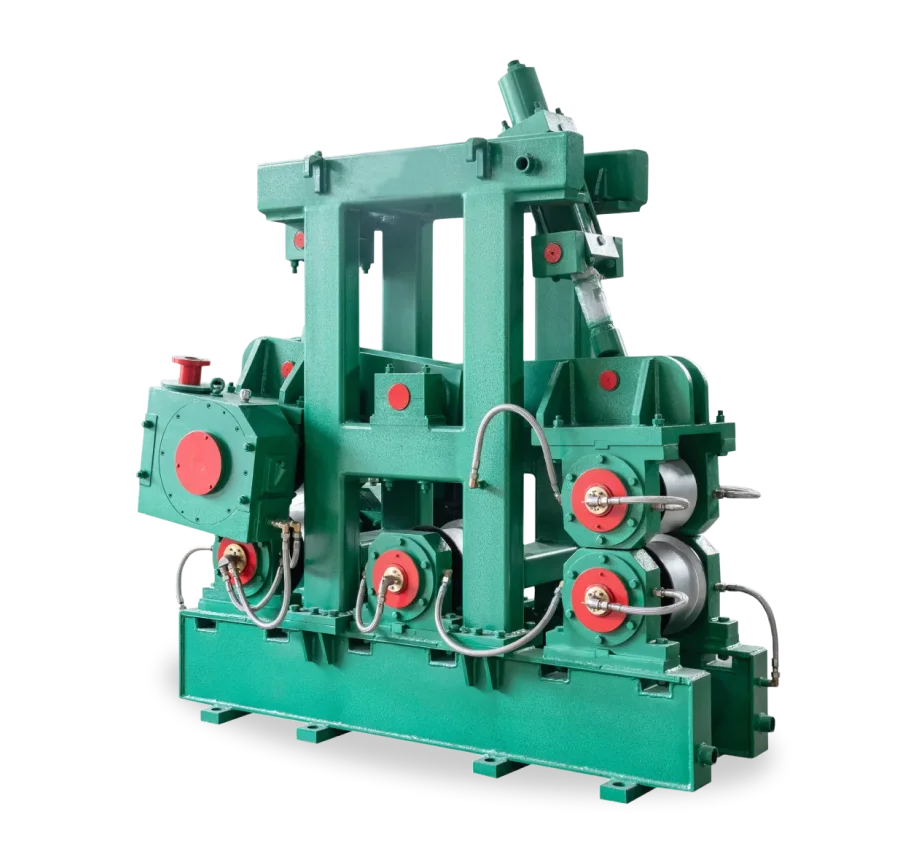

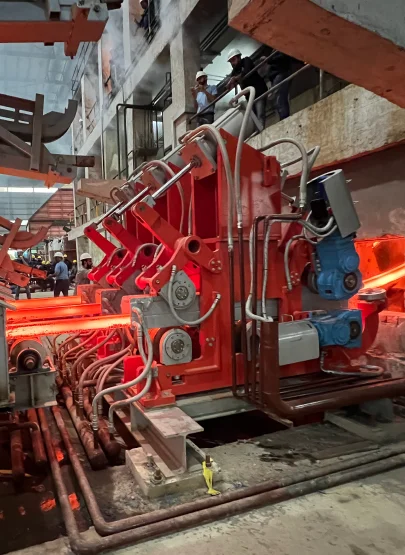

An efficient layout is critical for maximizing the effectiveness of any Continuous Casting Machine.

Unisons Steel Solutions services include detailed layout planning that considers spatial constraints, workflow optimization, and safety standards. We create layouts that facilitate smooth material flow, reduce bottlenecks, and support maintenance accessibility. Whether you're upgrading an existing facility or constructing a new one, our strategic layouts ensure the CCM operates at peak efficiency, enhancing productivity and operational safety.