Induction Furnace

Powering modern steel production.

An introduction to Induction Furnaces

Induction furnaces have become essential equipment in modern steelmaking, renowned for their efficiency, energy-saving capabilities, and adaptability to a wide variety of metals. Here, our aim is to provide an in-depth look at what they are, how they work, their types, benefits, and applications in the steel industry.

What is an Induction Furnace?

An induction furnace is an electrical furnace used primarily for melting metals and alloys, especially in steelmaking. Unlike traditional furnaces that rely on fossil fuels, induction furnaces operate using electric currents to generate heat. This unique mechanism makes them more efficient, eco-friendly, and precise for various industrial processes. For consultations regarding Induction Furnaces, reach out to us!

How does an Induction Furnace work?

1. Raw Materials Preparation

The process begins with selecting and preparing the raw materials, which typically include,

Ferrous Metals

This includes iron and steel scrap, sponge iron, pig iron, or high-quality scrap steel.

Alloys and Additives

Alloying elements like chromium, nickel, or manganese may be added for producing specific steel grades.

Fluxes and Slag Formers

Flux materials like limestone and dolomite may be added to remove impurities, forming a slag that floats to the surface and is removed.

The quality and cleanliness of the raw materials are essential for achieving the desired final properties in the steel. Scrap and other metallic inputs are often pre-processed to remove contaminants, moisture, and rust, improving the melting efficiency and minimizing unwanted impurities.

2. Charging the Induction Furnace

The selected raw materials are then charged. This is done either manually or with the help of automated charging systems, depending on the furnace design and production scale. In some setups, a crane or bucket system is used to load large volumes of material efficiently.

First Layer - Scrap Metal

The initial layer often consists of clean, larger pieces of scrap or pig iron.

Subsequent Layers

After the initial material melts down, other additives and alloys are added in controlled quantities to meet the desired chemical composition.

3. Induction Heating and Melting Process

The heart of the steel melting process is electromagnetic induction heating.

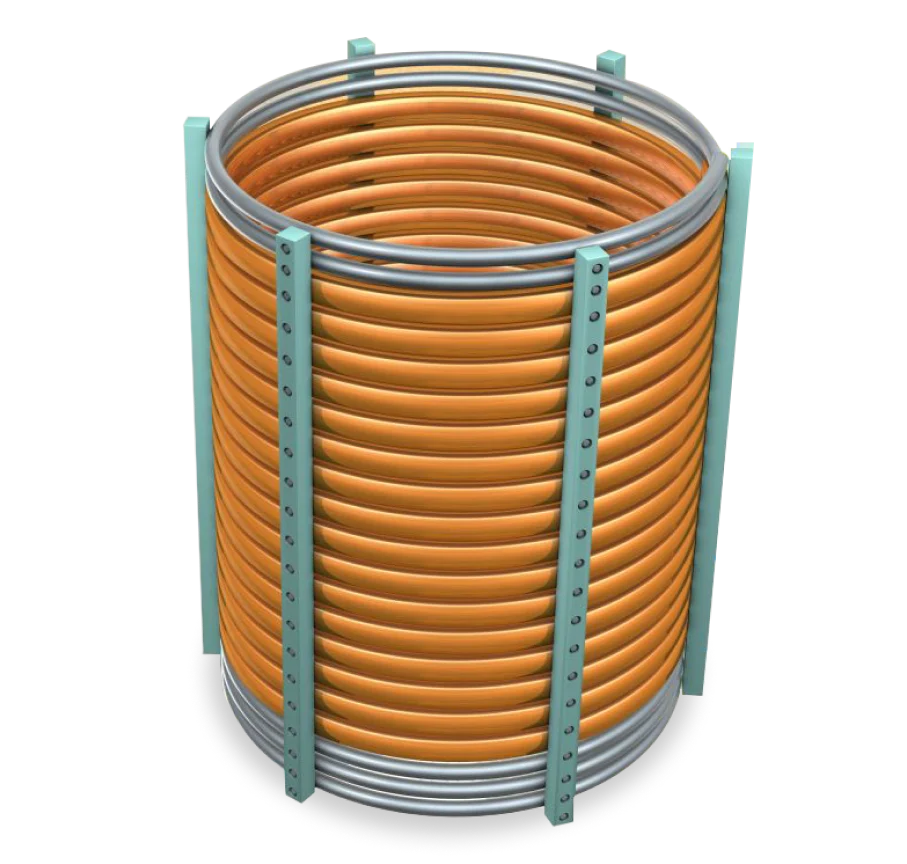

Coil and Magnetic Field Creation

When an alternating current (AC) is passed through a coil surrounding the furnace, it creates a powerful, alternating magnetic field.

Eddy Currents Formation

This magnetic field induces eddy currents in the metal charge, causing rapid internal heating and melting of the metals.

Stirring Effect

The electromagnetic force naturally stirs the molten metal, leading to a uniform temperature and composition throughout the furnace. This automatic stirring reduces the need for external mixing, ensuring even alloy distribution.

The temperature and power are closely controlled to melt the metal charge efficiently and safely. In steel production, the temperature typically ranges between 1500-1600°C

4. Addition of Alloys and Fluxes in the Induction Furnace

Once the metal reaches the molten state, operators may add alloying elements to achieve specific properties, such as strength, hardness, or corrosion resistance. Fluxes are sometimes added at this stage to form a slag layer that traps impurities and floats on the surface of the molten metal. The slag layer also helps prevent oxidation and keeps the metal pure.

5. Deslagging and Refining

As the melting process continues, impurities rise to the top, forming a slag. The deslagging process involves:

Skimming the Slag

Operators carefully remove the slag using specialized tools or automated skimming systems.

Refining the Melt

With impurities removed, the molten metal undergoes final adjustments to its chemical composition and temperature to meet the desired quality standards.

6. Induction Furnace Tapping

Once the molten metal has reached the optimal temperature and composition, it’s ready for pouring.

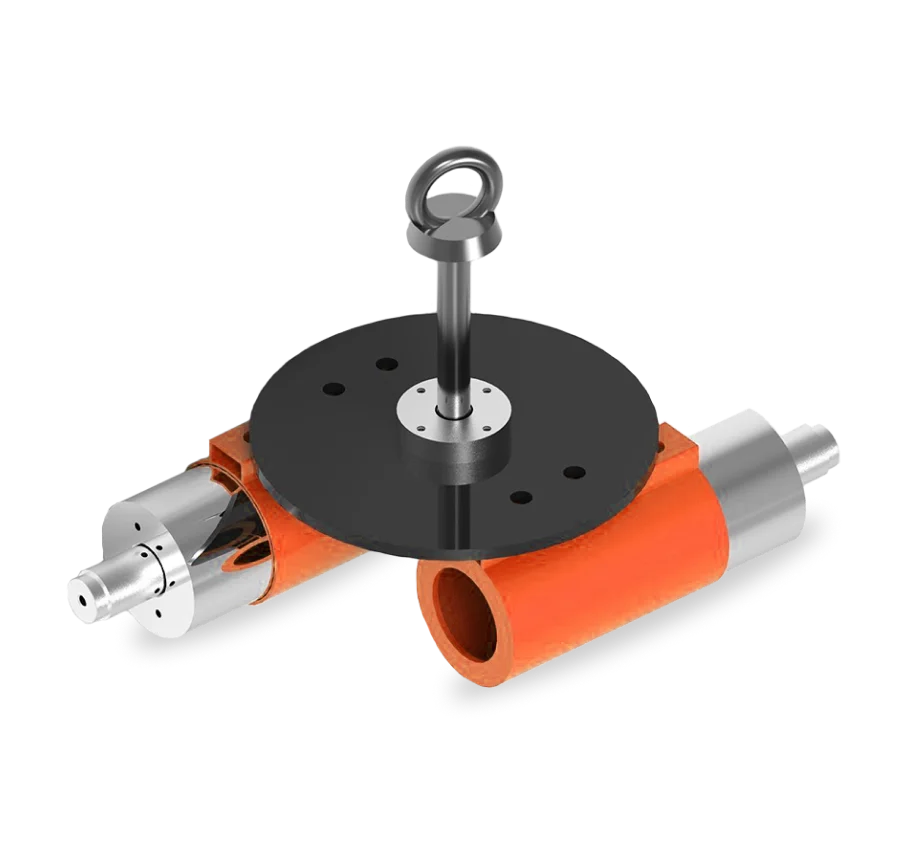

Tilting the Furnace

The furnace is then tilted, to allow for a controlled pouring of the molten metal.

Pouring into Ladle

The molten metal is poured into a ladle which is then transferred for further processing.

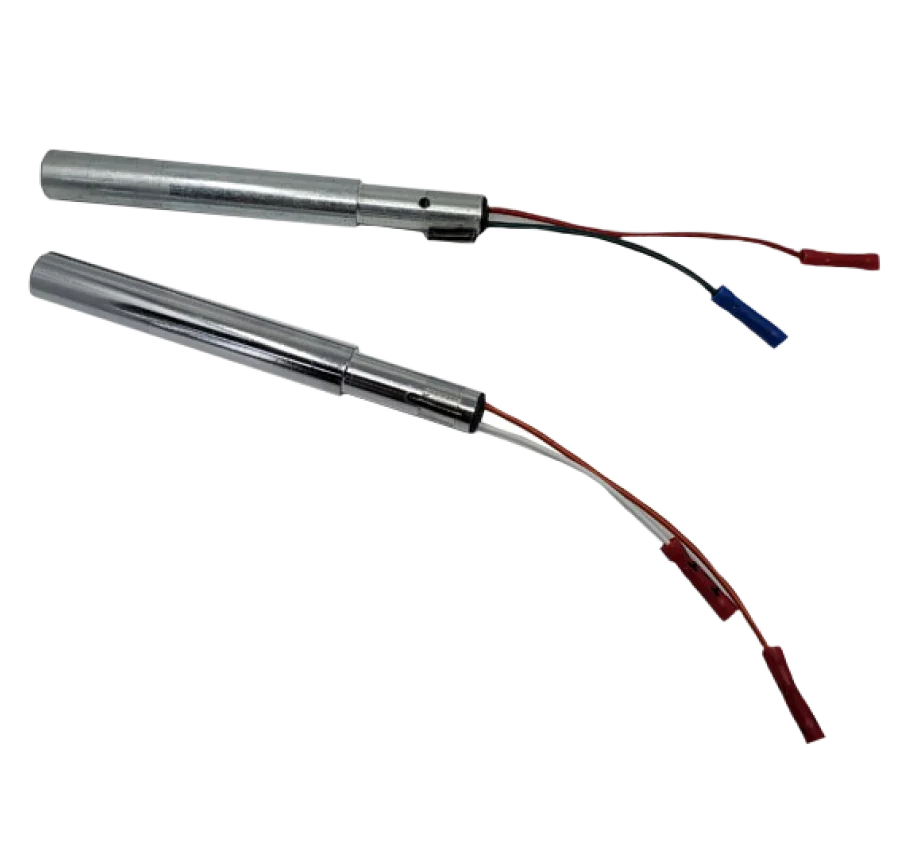

Spares & Consumables for Induction Furnace

To ensure smooth operations and high-quality steel production, Unisons Steel Solutions supplies several essential equipment that are required. Visit our Online Store for an extensive list of our products.

.webp)

Induction Furnace Services

Unisons Steel Solutions is staffed with industry experts and capable engineers to provide the complete Design for your melt shop, develop optimal Layout according to your Steel Mill and execute the commissioning for your Induction Furnace.

Yes, Unisons Steel Solutions has partnered with leading global manufacturers to supply complete end-to-end equipment and solutions to our customers for Induction Furnaces.

Our team of experts and consultants will analyze your requirements and your Steel Mill to offer you the most cost-efficient and optimal solutions for your Induction Furnace.

Contact us via email unisons@unisons.com.pk or salespk@unisons.com.pk with your requirements to receive a fresh quotation for your next Induction Furnace project.

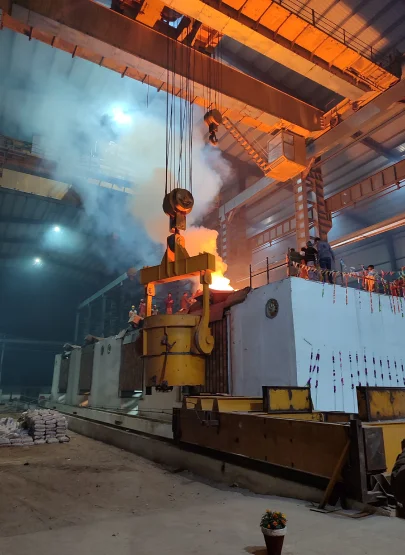

Induction Furnace Projects

Humza Steel 25 Ton Induction Furnace

Etihad Alloys Induction Furnace

.webp)

.webp)