Pearlitic Nodular Cast Iron Rolls in Pakistan

Pearlitic Nodular Cast Iron Rolls in Pakistan

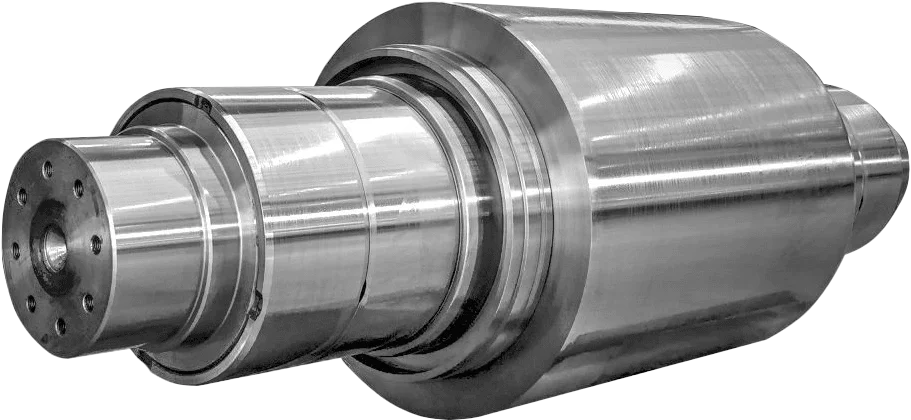

Achieve exceptional performance with Pearlitic Nodular Cast Iron Rolls—engineered for superior strength, wear resistance, and thermal stability. Ideal for various steel rebar production, these rolls deliver consistent quality and longevity even under demanding environments.

Request a Quote / Inquiry

High Performance Rolls for Long Service Life in Rolling Mills

Pearlitic Nodular Cast Iron Rolls are widely used in rolling mills across Pakistan due to their excellent balance of strength, wear resistance, and thermal stability. Manufactured with a nodular graphite structure and pearlitic matrix, these rolls provide superior durability, making them ideal for finishing stands, section mills, and bar mills.

At Unisons Steel Solutions, we supply Pearlitic Nodular Cast Iron Rolls in Pakistan that are engineered to deliver consistent performance, reduce roll consumption, and improve surface finish in steel production.

Technical Specifications of Pearlitic Nodular Cast Iron Rolls

Technical Data Table

| Property | Specification |

| Material Structure | Nodular graphite with pearlitic matrix |

| Hardness (Shore C) | 60 – 75 |

| Tensile Strength | 500 – 700 MPa |

| Typical Applications | Finishing stands, section mills, bar mills |

| Wear Resistance | High |

| Thermal Shock Resistance | Excellent |

| Surface Finish Quality | Superior to ordinary cast iron rolls |

- Material Composition: Made from high-grade nodular cast iron with a pearlitic matrix, providing a combination of toughness and hardness.

- Microstructure: The nodular graphite structure enhances ductility while maintaining high strength, reducing the likelihood of cracking under stress.

- Thermal Conductivity: Excellent thermal conductivity helps in heat dissipation, minimizing thermal stresses during operation.

Comparison: Pearlitic vs. Bainitic Nodular Cast Iron Rolls

| Property | Pearlitic Nodular Cast Iron Roll | Bainitic Nodular Cast Iron Roll |

| Matrix Structure | Pearlitic with nodular graphite | Bainitic with nodular graphite |

| Hardness (Shore C) | 60 – 75 | 70 – 85 |

| Tensile Strength | 500 – 700 MPa | 600 – 800 MPa |

| Wear Resistance | High | Very High |

| Thermal Shock Resistance | Excellent | Superior |

| Surface Finish | Smooth & consistent | Slightly rougher but very durable |

| Best Applications | Finishing stands, bar mills, section mills | Hot rolling mills, intermediate stands, heavy-duty rolling |

| Service Life | Long | Longer under heavy load conditions |

Key Takeaway:

-

PNCIR → Best for finishing applications where smooth surface finish is critical.

-

BNCIR → Ideal for heavy-duty, high-load rolling with superior wear resistance.

Key Features of Pearlitic Nodular Cast Iron Rolls

-

High wear resistance for extended rolling campaigns

-

Strong nodular graphite structure for toughness and crack resistance

-

Excellent thermal shock resistance under continuous rolling

-

Suitable for both hot and cold rolling applications

-

Provides better surface finish compared to standard cast iron rolls

Applications

-

Steel Rolling Mills – section and bar rolling

-

Re-rolling Mills – improved wear life in high-load operations

-

Wire Rod & Structural Mills – consistent output with reduced downtime

Why Choose Us?

-

High-quality rolls engineered for Pakistan’s steel industry

-

Reliable after-sales service and technical support

-

On-time delivery across the country

| High Wear Resistance | The pearlitic structure significantly reduces wear, prolonging roll life and minimizing maintenance needs. |

|---|---|

| Reduced Surface Defects | Enhances the quality of finished products by minimizing surface imperfections. |

| Cost-Effective Solution | Long-lasting performance leads to lower operational costs and reduced downtime in steel manufacturing. |

Reviews

There are no reviews yet.