Cast Rolls with Grooves in Pakistan

Cast Rolls with Grooves in Pakistan

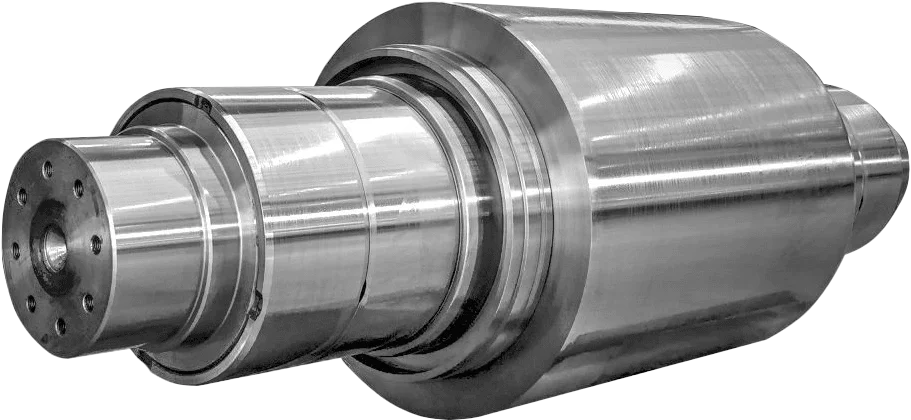

Looking for durable and high-precision grooved cast rolls for your re-rolling mill? Our Cast Rolls with Grooves are manufactured to provide excellent performance in hot rolling applications across Pakistan’s steel industry.

These rolls are specially designed for primary and intermediate stands, enabling accurate shaping of bars, TMT rods, and structural steel with minimal wear and consistent groove geometry.

Request a Quote / Inquiry

Cast Rolls with Grooves in Pakistan – Precision Engineered for Steel Re-Rolling Mills

What Are Cast Rolls with Grooves?

Cast Rolls with Grooves are metal rolling components featuring pre-machined grooves used to form steel into specific shapes like round bars, square sections, flats, and angles. Made from alloy cast iron or cast steel, they provide a balance between wear resistance, thermal shock resistance, and toughness.

Technical Specifications

| Specification | Details |

| Material | Cast Iron / Cast Steel / Alloy Cast Iron |

| Groove Types | Single, Double, Triple, Custom |

| Hardness Range | 35–65 HSD (depending on material) |

| Outer Diameter Range | ⌀300 – 800 mm |

| Barrel Length | 500 – 2000 mm |

| Working Temperature | Up to 700°C |

| Surface Finish | Machined and ready for assembly |

| Application Area | Intermediate and roughing stands |

- Material Composition: Made from alloyed cast iron with high wear-resistant properties to withstand the rigors of shaping operations.

- Precision Groove Design: Grooves are cast to exact specifications, allowing for precise shaping and ensuring uniform dimensions across products.

- Hardness and Durability: Engineered with high surface hardness to maintain groove profile even under high loads and temperatures.

Key Features & Benefits

-

Precisely machined grooves for dimensional accuracy

-

High resistance to thermal and mechanical stress

-

Supports longer rolling campaigns without frequent redressing

-

Available in single, double, or triple-grooved configurations

-

Ideal for bar mills, section mills, and TMT production lines

Common Applications in Pakistan

Our grooved cast rolls are widely used in:

-

Steel Re-Rolling Mills

-

TMT Bar Rolling

-

Flats and Angles Production

-

Section Mills and Merchant Mills

Their precise groove design ensures uniform cross-section and minimal deviation in final products — critical in meeting both domestic and export quality standards.

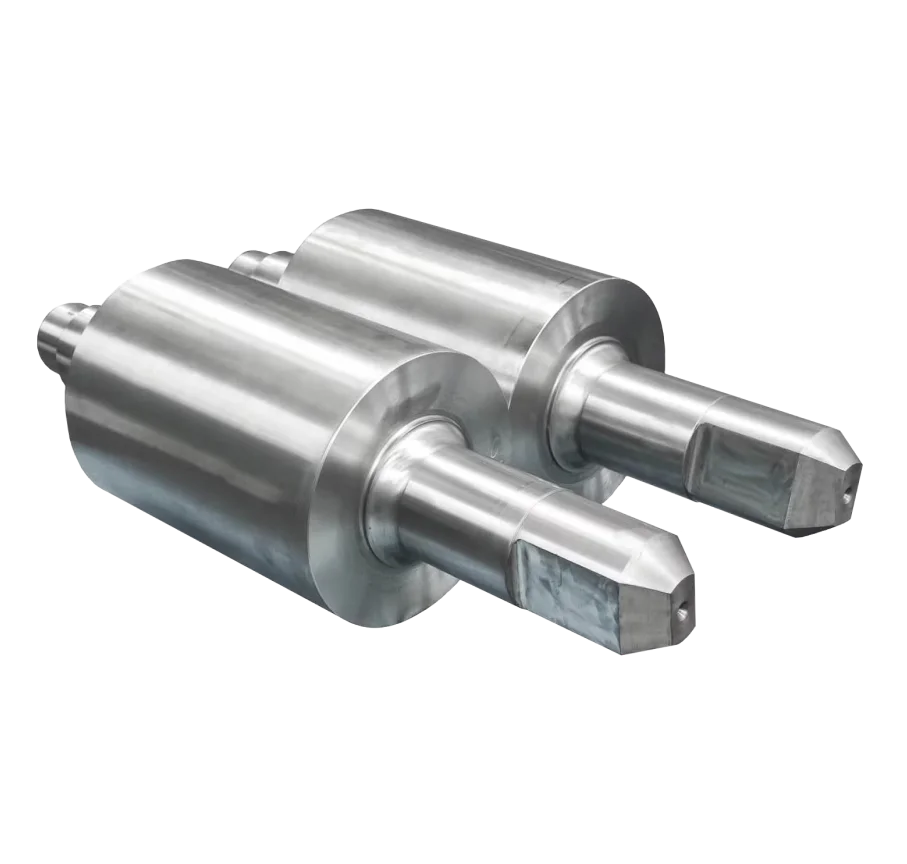

Available Types of Grooved Rolls

| Type | Groove Configuration | Ideal Application |

| Single-Groove | 1 Wide Groove | Light and medium-section rolling |

| Double-Groove | 2 Grooves (equal/unequal) | Continuous production lines |

| Triple-Groove | 3 Grooves | High-volume rebar or rod production |

| Custom-Grooved | As per drawing | Special sections / customer specifications |

Why Order From Us?

- Pakistan-wide delivery

- Custom groove designs available

- Backed by decades of industry experience

- Technical support & roll pass design consultation

We ensure all rolls meet international metallurgy and performance standards, serving small to large-scale mills across Pakistan.

Get a Quote Now

Ready to optimize your rolling operations?

Contact us today for quotes, groove drawings, or custom manufacturing requirements.

| Consistent Product Quality | Provides uniform groove profiles that ensure precision shaping, reducing material waste and enhancing product uniformity. |

|---|---|

| Long Service Life | Manufactured to resist wear, thermal stress, and impact, these rolls offer an extended operational lifespan, minimizing replacement needs. |

| Efficient Steel Shaping | Designed for smooth, reliable shaping of steel, reducing production time and enhancing throughput in rolling processes. |

| Reduced Maintenance Costs | Engineered to maintain groove profiles over prolonged usage, reducing downtime and maintenance expenses. |

Reviews

There are no reviews yet.