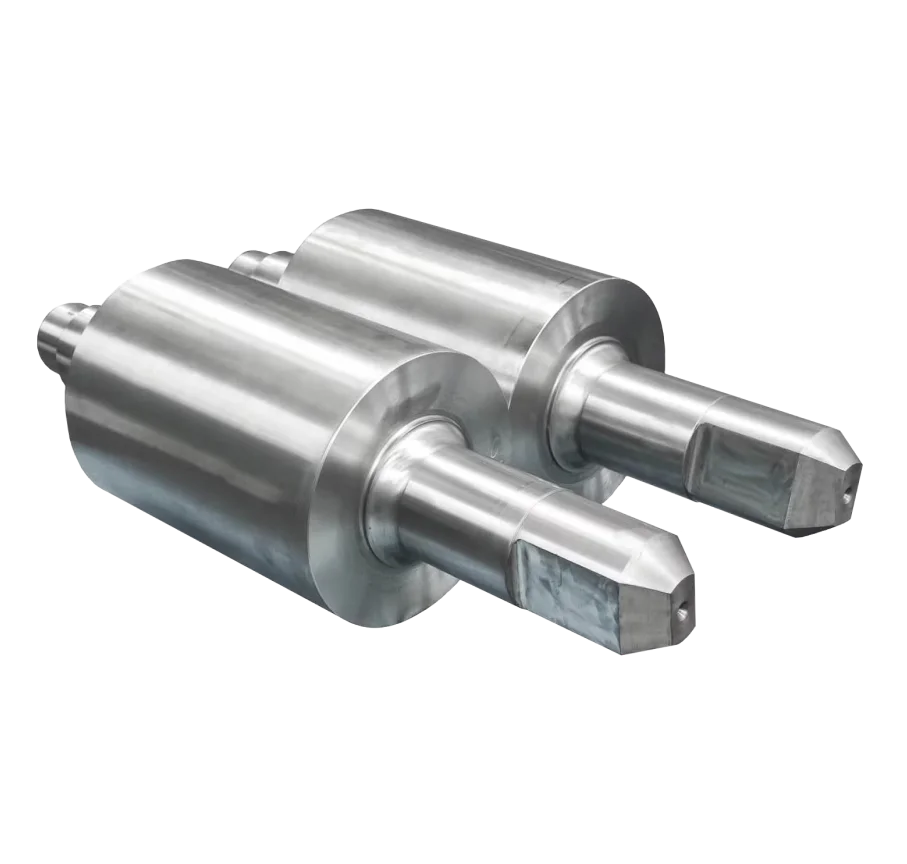

Alloy Indefinite Chilled Cast Iron Roll

Alloy Indefinite Chilled Cast Iron Roll

Boost your mill’s efficiency with our Alloy Indefinite Chilled Cast Iron Rolls—engineered for durability, thermal resistance, and consistent performance in the toughest rolling conditions.

Request a Quote / Inquiry

Alloy Indefinite Chilled Cast Iron Roll – Precision Rolling Performance

Our Alloy Indefinite Chilled Cast Iron Rolls (ICCI Rolls) are designed to deliver high performance in intermediate and finishing stands of rolling mills. These rolls are alloyed with Nickel, Chromium, and Molybdenum to enhance wear resistance and strength, making them suitable for a wide range of rolling applications in steel and non-ferrous metal production.

The indefinite chill microstructure includes a matrix of graphite and carbide dispersed in pearlitic or bainitic background, allowing superior heat dissipation and excellent surface finish on rolled products.

Technical Specifications of Alloy Indefinite Chilled Cast Iron Roll

| Property | Details |

| Material | Alloy Indefinite Chilled Cast Iron |

| Hardness (Shore C) | 65–85 |

| Chill Depth | 15–30 mm |

| Tensile Strength | ≥ 400 MPa |

| Microstructure | Pearlitic / Bainitic + Carbides |

| Graphite Type | Fine Flake Graphite |

| Core Material | SG Iron / Nodular Cast Iron |

- Material Composition: Crafted from a blend of iron and specific alloying elements, resulting in a chilled structure that enhances hardness and durability.

- Chilled Surface: The surface of the rolls is treated to achieve a high hardness level, offering excellent wear resistance and extending the operational lifespan.

- Thermal Stability: Designed to withstand thermal stresses and fluctuations during the rolling process, ensuring consistent performance.

Key Features

-

High wear resistance and surface hardness

-

Good thermal conductivity and crack resistance

-

Reduced roll changing frequency

-

Extended service life under continuous casting conditions

-

Excellent dimensional stability and surface finish

Applications

-

Bar Mills

-

Section Mills

-

Wire Rod Mills

-

Hot Strip Mills

-

Non-Ferrous Rolling

Available Sizes

| Roll Diameter (mm) | Roll Length (mm) | Neck Diameter (mm) | Application Area |

| 300 – 850 | 500 – 2200 | 150 – 350 | Bar/Section/Wire Rod Mills |

Why Choose Our ICCI Rolls?

With a proven track record in steel plants across Pakistan and international markets, our Alloy Indefinite Chilled Cast Iron Rolls ensure better rolling consistency, reduced downtime, and cost-effective production for your mill operations.

| Exceptional Wear Resistance | The alloy composition and chilling process significantly improve wear resistance, reducing the frequency of roll replacements and maintenance costs. |

|---|---|

| High Strength and Toughness | Designed to withstand high-impact loads, minimizing the risk of cracking or deformation during operation. |

| Consistent Product Quality | Maintains dimensional accuracy and surface quality, ensuring high-quality output in steel production. |

| Cost-Effective Solution | Extended service life translates to lower operational costs, improving overall productivity in steel manufacturing processes. |

Reviews

There are no reviews yet.