Top 5 Metrics Industrial Performance Metrics

Monday, April 21, 2025

How Energy Prices Are Impacting Steel Production in Pakistan

Wednesday, June 11, 2025INDUSTRIAL DIGITALIZATION

Importance of Sensors in the Steel Industry

DELTA SENSORS & SYSTEMS - OFFICIAL BUSINESS PARTNER OF UNISONS

Use of Sensors in the Steel Industry

Why are Sensors Important?

The Power of Sensors

In the highly demanding environment of the steel industry, precision, safety, and speed are non-negotiable. Sensors play a critical role in ensuring these standards are met across every stage of production. From monitoring molten metal movement to positioning heavy rolling equipment, sensor-based automation enhances accuracy and minimizes human error.

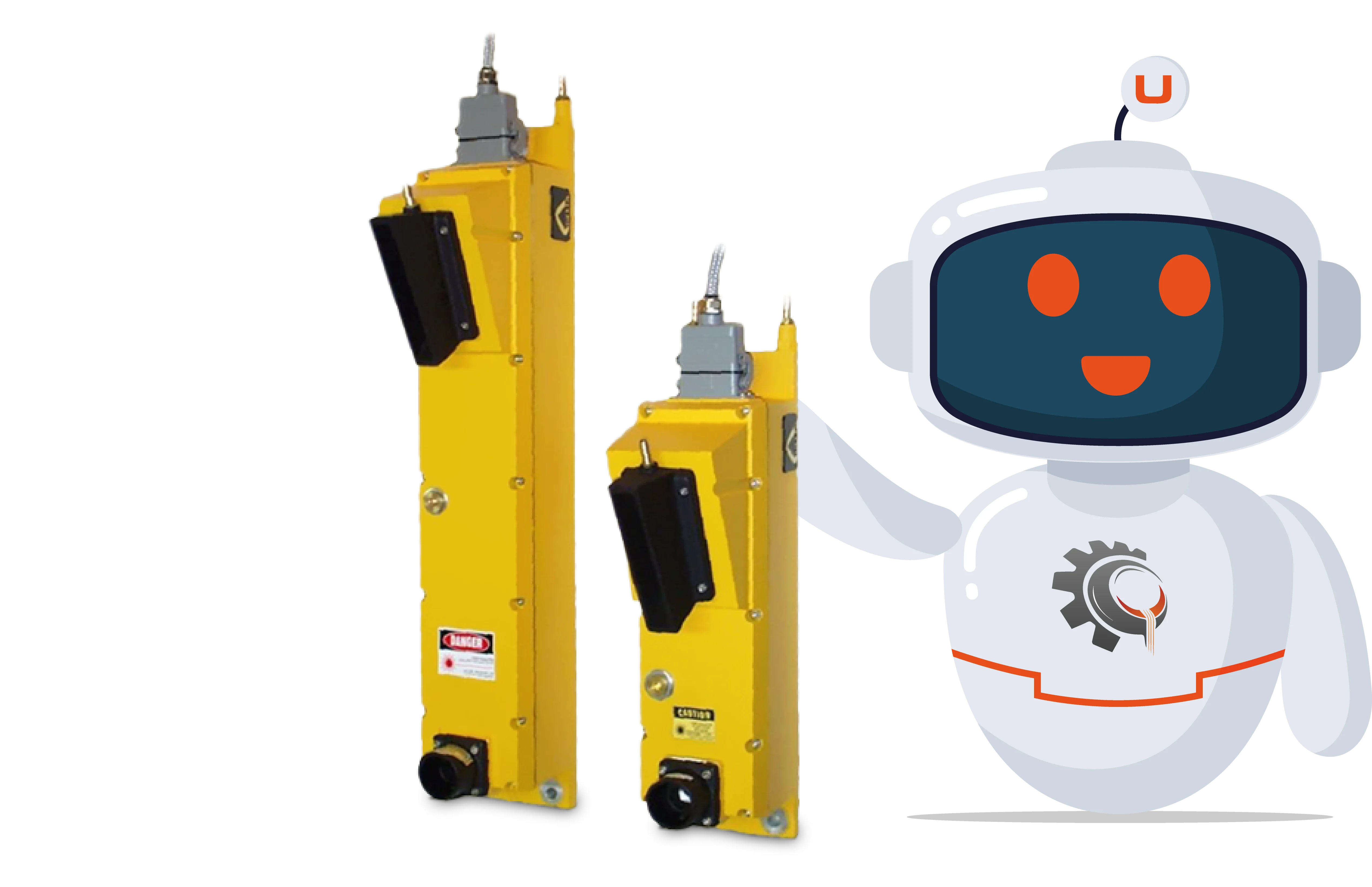

Delta Sensors & Systems - Official Business Partner of Unisons in Pakistan

Unisons has partnered with one of the leading manufacturers of industrial sensors—Delta Sensors and Systems— that provides robust and reliable solutions tailored for steelmaking environments. The following are some of the key sensor types that have become essential in steel plants:

1. Loop Scanner

Loop scanners are crucial for managing the position of steel strips during the rolling process. They help in maintaining correct tension and alignment of the strip, preventing production defects and equipment damage.

Why they matter: Accurate loop control ensures consistent material flow, reducing the risk of breakage or uneven rolling.

2. Hot Metal Detector (HMD)

Hot metal detectors are designed to detect the presence and exact location of hot steel products. These sensors are vital for automated positioning, cutting, and transportation operations.

Why they matter: HMDs work in extremely high-temperature zones where human access is risky. They help automate safety-critical decisions with split-second precision.

3. Infrared Temperature Sensors

These sensors are used to measure the temperature of slabs, billets, and other hot products in real time. Delta’s infrared sensors are engineered to withstand the harsh conditions of steel mills.

Why they matter: Accurate temperature monitoring enables better process control, especially in heating and cooling phases.

4. Proximity and Position Sensors

These sensors are used to monitor the position of actuators, conveyors, and product flow in various production stages.

Why they matter: They ensure synchronized movement of equipment and material, improving coordination and reducing delays.

5. Laser Distance Sensors

Laser-based sensors help with measuring the dimensions and alignment of hot and cold products.

Why they matter: Dimension control is vital for product quality and standard compliance in rolled and formed steel goods.

How Unisons can help you track Industrial Performance Metrics

Adopting Real-time Monitoring.

Whether your facility is already automated or still operating with manual processes, tracking key performance metrics is essential for long-term success. At Unisons, we help industries not only implement automation but also identify and monitor the KPIs that truly matter. From production analytics to energy dashboards, we provide smart, scalable solutions that turn raw data into actionable insight.

Industrial Digitalization Solutions from Unisons

Industrial performance metrics

At Unisons, we specialize in digital transformation solutions for various industries, including steel, cement, glass, fertilizer manufacturing and various others. We are able to provide software solutions, custom-tailored to your needs, which enable you to,

1. Automate industrial processes

Automate your day-to-day tasks, streamlining operations and minimizing manual intervention, reducing the risks of human errors.

2. Monitor and control multiple production units

Our software solutions allow real-time data analysis across multiple production sites through a single unified platform, enabling improved decision making.

3. Implement AI-driven predictive maintenance

Minimize downtime and increase efficiency by identifying potential equipment failures before they occur.

4. Enhance data security and compliance

Robust digital frameworks, ensuring industrial data integrity and protection against cyber threats.

Digitalize your Industry

Digitalization automates data collection, reduces human errors, speeds up reporting, and allows real-time monitoring, leading to improved decision-making and operational efficiency.

Industries such as steel, cement, glass, manufacturing, and energy sectors benefit greatly from digitalization due to the need for efficiency, real-time monitoring, and process optimization.

Our team of experts will start by assessing your current manual processes, identifying key areas for improvement, to implement the right solutions tailored to your operations.