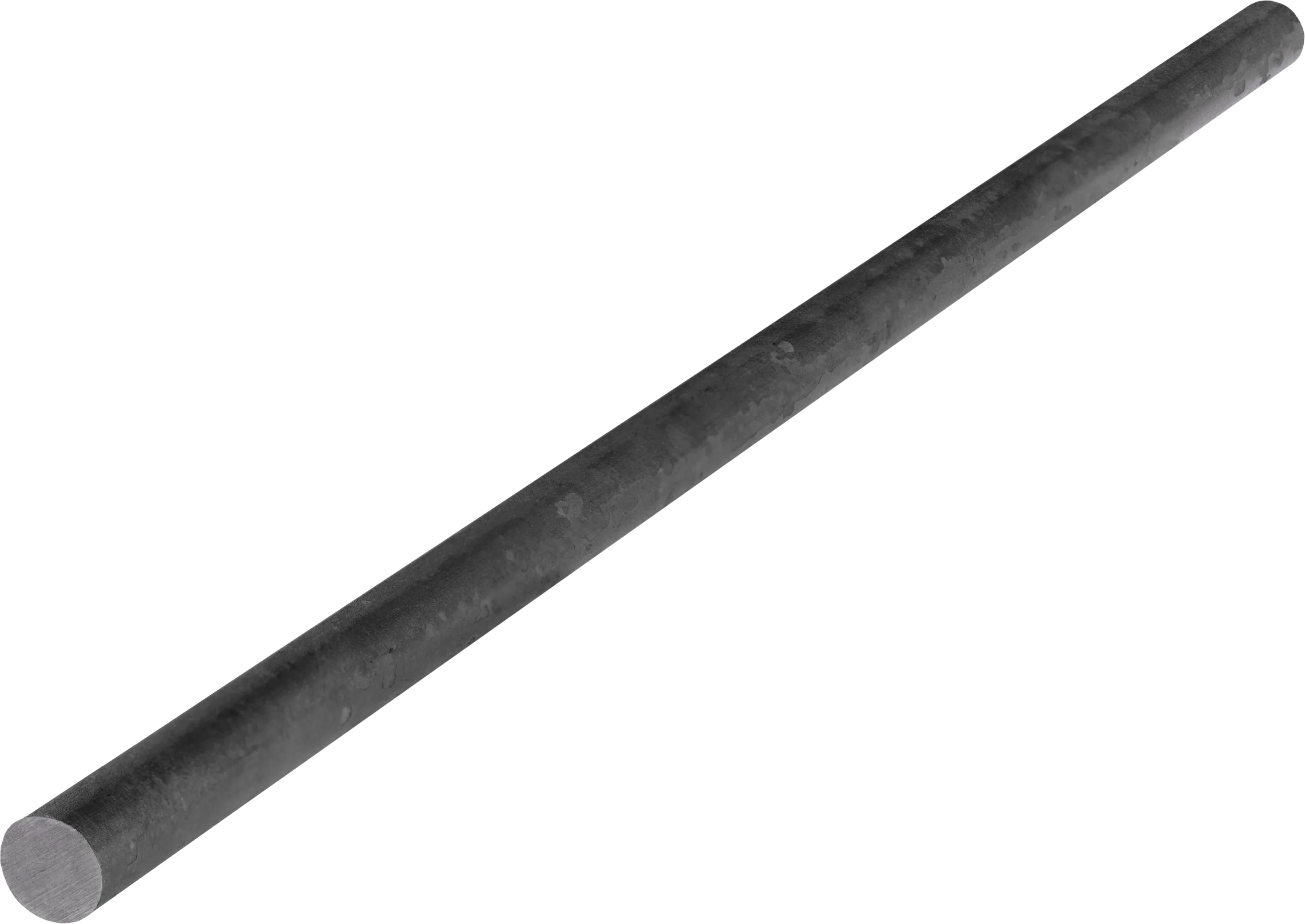

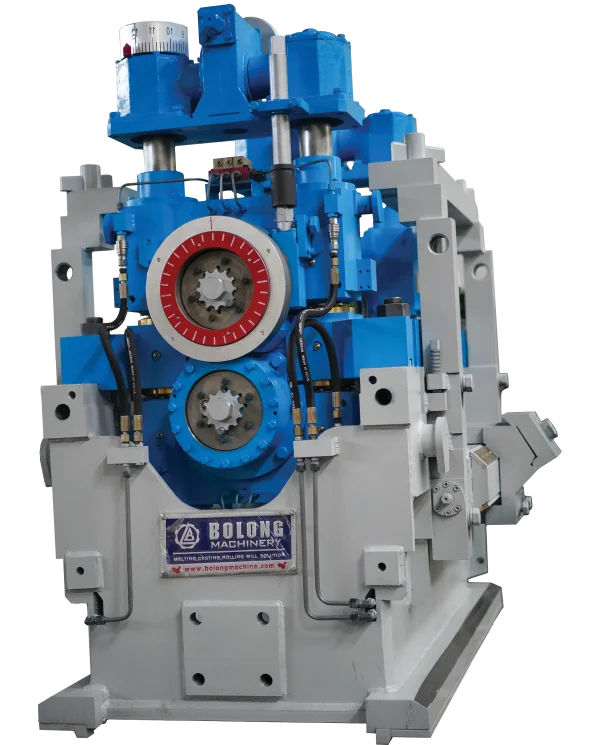

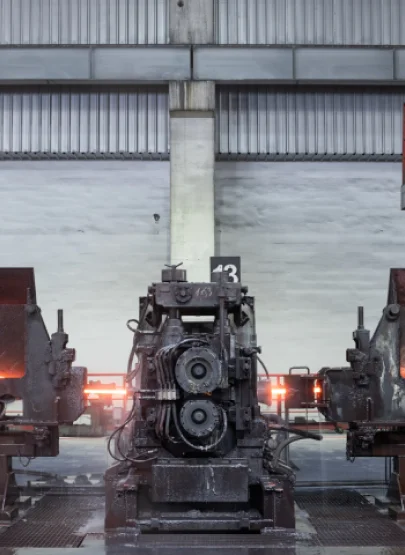

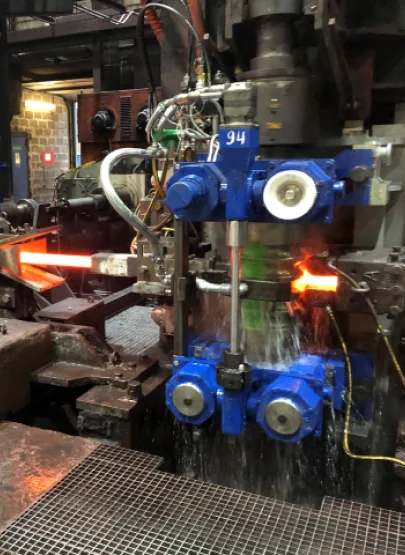

An effective layout is vital for the smooth operation of Rebar Rolling Mills.

Our consultancy services include comprehensive layout planning, which takes into account factors such as material flow, safety, and maintenance access. We design layouts that facilitate efficient handling of raw materials and finished products, reducing bottlenecks and maximizing throughput. By optimizing the spatial arrangement of the rolling mill components and auxiliary systems, we help you achieve enhanced operational efficiency, ensuring a streamlined workflow that supports high production rates.